|

|

|

|

Unprecedented air infection prevention

There is a strong need to prevent the air infection such as the bioterrorism, the hospital-acquired infections and the pandemic influenza from occurring in anywhere in the world every year. With the advances in medical technology, the environmental development is becoming a major issue for the prevention of hospital-acquired infections in hospitals and in nursing homes caused by multidrug-resistant bacteria of MRAS, etc. and also for the prevention of the secondary infection with clean room installation.

Learning from our ancestors that people in the past killed microorganisms by all incineration to prevent the spread of infection when the ancient epidemic occurred, we have developed a heat sterilization equipment which provides the clean air by sterilizing bacteria scattered in the air with a super high temperature.

Simple purification

One-pass sterilization by heating

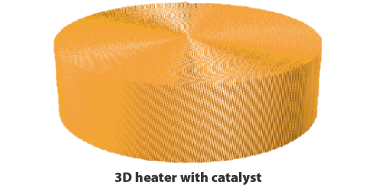

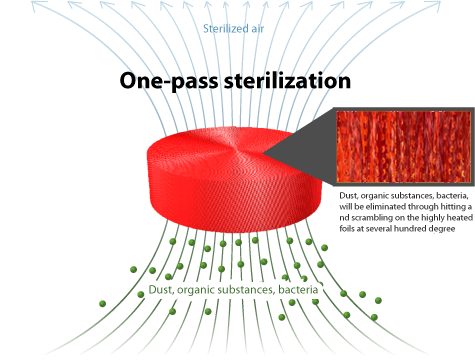

The experiment confirmed that the bacteria of organic matter, pollen and even micro-sized dust were disappeared completely by 3D heater heated up to 350°C or higher.*

The Perfect Clean is composed of the 3D heater, the blower and the air-cooled heat exchanger. This is the only device with "one-pass sterilization" capability in the world which disappear in a single pass all bacteria floating in the air no matter how badly it is contaminated.

* In sterile experiments with spore-forming bacteria which has strong resistance to heat, it proved that all bacteria are completely disappeared at 300°C or higher. (Experiments in Kyoto Prefectural University of Medicine)

Friendly purificatio

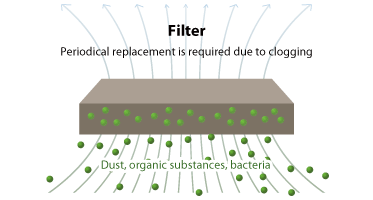

Filter unnecessary for heat sterilization

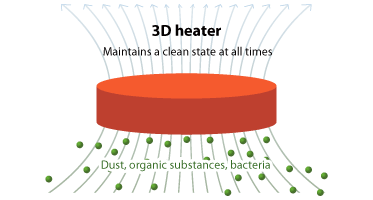

In 3D heater used in Perfect Clean, it sterilizes bacteria with high heat to hold a clean state at all times.

In the filter process, there is a possibility of bacteria to re-float even after being caught. The heat sterilization of Perfect Clean can eliminate the bacteria itself and that no bacteria will be possible to re-float.

As a result, it will become the maintenance-free for 365 days and that no filter replacement is needed (zero maintenance cost) nor any more medical industrial waste is generated.

Solid purification

Cut off the bacteria to breed in the air-cooled heat exchanger

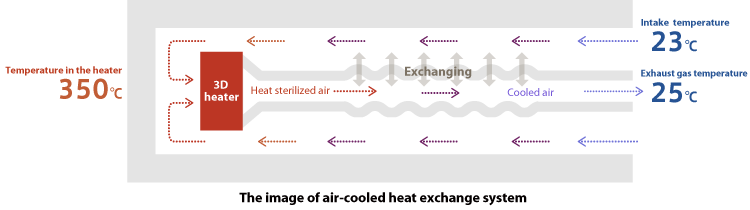

The air that has been cleaned with Perfect Clean is discharged after cooling down to 2°C more than the intake room temperature.

The cooling system is a super air-cooled heat exchange system with unprecedented features. The heat exchange was accomplished by exchanging the heat between the exhaust heated air and the intake air to capture.

In the refrigerant system commonly used in cooling system, the water droplets due to the condensation might give the place for bacteria to breed. In the air-cooled heat exchanger system, however there is neither condensation nor breeding place of the new fungus born. Therefore this is the best cooling system for the sterilizer.

Pure purification

Odor removal by heat sterilization

By applying the catalytic treatment on the 3D heater, a Perfect Clean with the deodorizing function is created. In addition to the perfect sterilization, it is a unprecedented heat sterilization equipment which can be utilized as an air purifier to discharge the clean air without any smell.

The platinum-supported catalyst employed has the deodorization to remove the ammonia, the amines, the ethyl acetate and the aromatic odor (benzene compound).